The Problem with Bioplastics

by Alex Blum, Co-founder/CEO at Applied Bioplastics

It’s a cycle that repeats maddeningly, isn’t it? You, the sustainability-minded consumer/investor/business owner, read an article about a new plastic that promises to solve the climate and plastic waste crisis in one fell swoop. Then…. nothing. You never hear of them again. You search for them online and all you can find is the original article, and nothing else. Why haven't bioplastics gained widespread use in the market apart from PHA/PLA? These only make up a small percentage of the market share and are only more environmentally friendly for a limited range of applications and in one aspect of sustainability.

Maybe we should back up a bit. Bioplastics are a type of plastic derived from renewable biomass sources such as vegetable fats and oils, plant-based cellulose or starches, or some combination of the above. They are often touted as a more sustainable alternative to traditional petroleum-based plastics, as they can reduce reliance on fossil fuels and produce fewer greenhouse gas emissions. However, despite these potential benefits, bioplastics remain unpopular, expensive, and difficult to scale.

One reason for the unpopularity of bioplastics is the confusion surrounding the term itself. Bioplastics can refer to a variety of materials, each with different properties and uses. Some bioplastics like PHA are fully biodegradable, while others like PLA are only partially biodegradable or not at all. Some can be recycled with traditional plastics, while others cannot. The lack of standardization and clear labeling can make it difficult for consumers to understand the environmental impact of the products they are buying and using. This creates trust issues with users, which creates unpopularity.

Another reason for the unpopularity of bioplastics is the perception that they are less durable and have inferior properties compared to traditional plastics. This is partly because bioplastics are often derived from organic materials, which can have variable quality and consistency. Additionally, bioplastics may not be able to withstand the same high temperatures and pressures as traditional plastics, which can limit their use in many applications. This perception of inferiority can make it difficult for bioplastics to gain traction in the market, even if they are more sustainable in the long run.

In addition to these issues of perception, bioplastics are also nearly universally more expensive than traditional plastics. This is because the raw biomass materials used to produce bioplastics are often more expensive than petroleum-based feedstocks. They also have limited availability, and the competition with other industries that also use these resources drives prices even higher. Also, the capital equipment to produce them is custom-made, and bioplastics require a significant investment in research and development to optimize their properties and production processes. Because of this research requirement, production processes for bioplastics are more complex and require specialized expertise that’s uncommon in the job market. These factors contribute to a higher cost per unit of bioplastics compared to traditional plastics, which can make it difficult for manufacturers to justify the switch.

Availability is another challenge for the production of bioplastics currently on the market. While bioplastics have been around for decades, they still only represent a small fraction of the global plastic market. The requirement of custom equipment creates long lead times for scale, and if the resultant polymer doesn’t use industry-standard equipment for its end use, it is dead on arrival: there’s over half a trillion dollars worth of capital equipment globally that’s dedicated to using normal plastic, and if a new material doesn’t drop in easily to standard equipment, no one will buy it.

Furthermore, the disposal of bioplastics can present challenges at end of life. While some bioplastics are designed to be fully biodegradable, others require specific industrial composting conditions to break down properly. This can limit the options for disposal and create additional costs for waste management. Biodegradable plastics can still contribute to pollution if they are not disposed of properly, as they can release methane and CO2 when they break down during degradation. PLA produces between 3.3 and 3.7 kg CO2 equivalent per kg of resin, depending upon the disposal method (landfill vs. composting) and the amount of degradation.

Companies succeed when they can reduce the number of “miracles” necessary to scale. Bioplastics companies face a dozen: costly inputs, custom equipment, entrenched customers, expensive-to-replace processing equipment, poor mechanical properties, poor temperature stability, lack of regulation and standards, high unit costs, reluctance from investors who’ve been burned by the dozen previous “miracle” plastics, competition with food and fuel, lack of disposal infrastructure, and unanticipated externalities from improper disposal. Even if they somehow manage to solve all these issues, they still need to compete with commodity-priced incumbent petrochemical plastics.

Our focus at Applied Bioplastics has been on the issues that have plagued bioplastics commercialization to reduce the number of miracles necessary to succeed. By solving the cost problem with a product that drops into standard injection molding equipment, we’ve been able to overcome two major barriers to widespread adoption. Perhaps most importantly, our technology can be used by large petrochemical players to reduce the carbon footprint of their material without requiring new production equipment. Here’s hoping we break the depressing cycle of exciting materials that fall by the wayside at a time when humanity needs solutions more than ever.

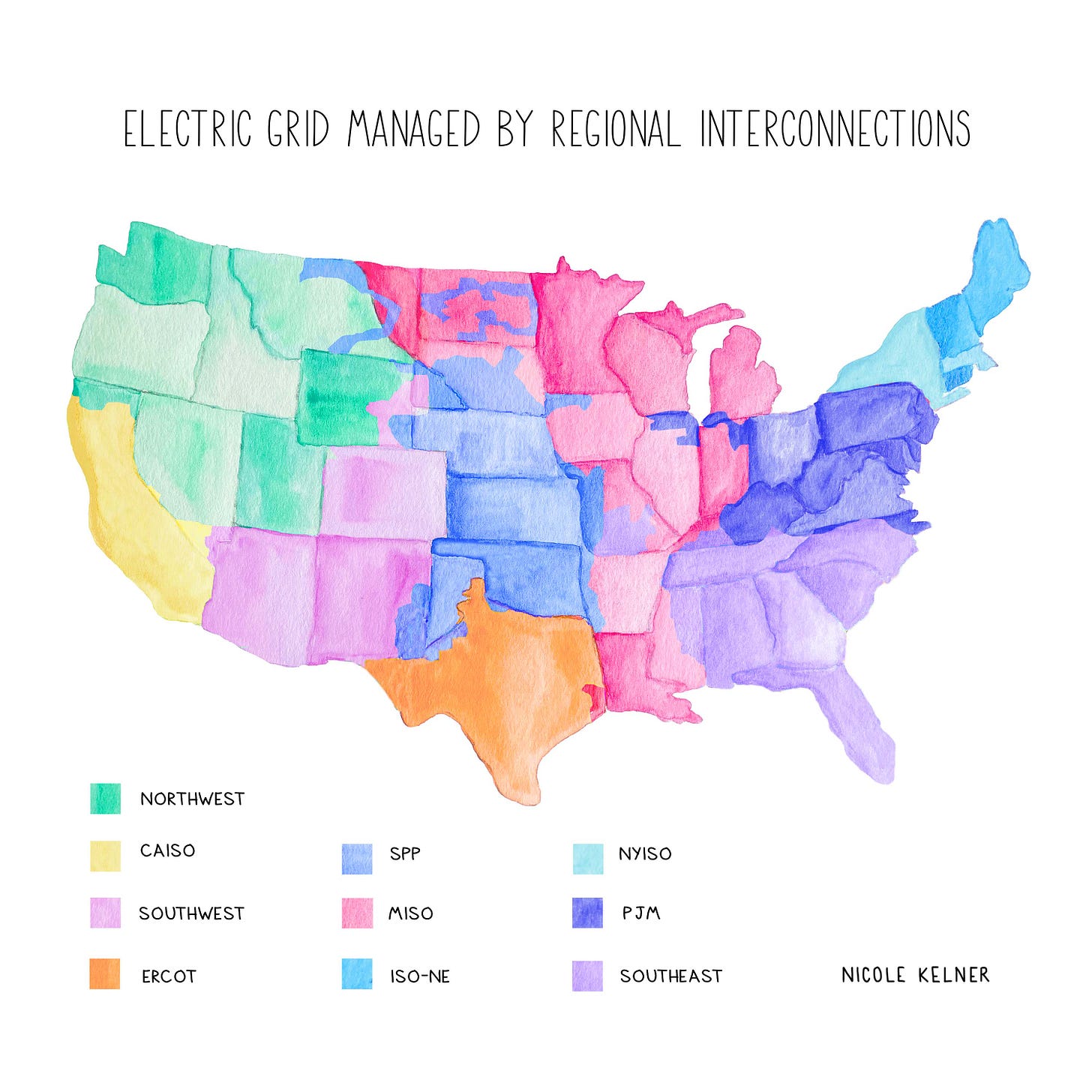

✍️ The Draw-down

Weekly climate art by our MCJ Artist-in-Residence, Nicole Kelner.

🎙My Climate Journey Podcast

🌇 Cody chatted with John Kinney, Founder, CEO and Managing Partner at CleanFund, about PACE financing options and his company’s role in helping property managers and lenders unlock new tools to finance clean energy upgrades.

🌱 Jack Morrison, Co-founder and CEO at Scythe, discussed their product line of autonomous electric commercial lawnmowers and how Scythe is pioneering a new usage-based model to offer a more sustainable way for landscaping companies to manage their cashflows and help employees get the job done.

🚨 MCJ Collective Job Alert

We're looking for a part-time Community Ops Associate to oversee our application and onboarding systems, and assist the talent pipeline between community members and portfolio companies. Think you're the right person for the job or know someone who would be a perfect fit? Apply here

✨ Highlights

🗓 April Events

Click the event title for details & RSVP info. For more climate events, check out the #c-events channel in MCJ Slack.

🙋♀️ MCJ AMA: Gustaf Alströmer - Y Combinator: HAPPENING NOW! Head over to #c-mcj-ama Slack channel to ask Gustaf your burning questions! The session ends tomorrow at 9am PST / 5pm GMT.

👋 Community Welcome Call: Connect, share and learn with the MCJ team and community members. (4/06)

🎓 College to Climate Monthly: Founded by university students eager to make an impact in climate tech but unsure of how to get there. Get closer to the action by building your climate network with professionals who have already traveled their own path. (4/11)

👨💻 MCJ Climate Career Advancement Meetup: If you are thinking about advancing your career to work in climate, please join us for an hour of learning and networking. (4/12)

🤝 Seattle Climate-Tech Meet Up: The objective here is to have fun. This is a free-flowing, come-and-go-as-you-see-fit sort of event. We simply coordinate a location and the rest is up to you. (4/12)

🏙️ MCJ Monthly Idea Jam, Built Environment: These sessions provide a chance for MCJ members to get help with roadblocks, meet co-founders or future employees, connect with investors, or people working on similar topics. (4/14)

🇫🇷 MCJ Paris Networking Event: Matthieu Soulé who is the San Francisco MCJ community host at night will be visiting Paris and would love to connect with you all locally. (4/17)

🌳 MCJ AMA: Diego Saez-Gil (Pachama) & Sam Gill (Sylvera): Catch up on Diego and Sam’s podcast episode here. Register for the AMA event here. (4/19)

📚 MCJ Book Club: Join us for a discussion of Regeneration by Paul Hawken. We'll discuss the ideas presented in the book. (4/19)

MCJ Climate Voices is a free weekly email curating news, jobs, My Climate Journey podcast episodes, and other noteworthy happenings in the MCJ member community.

💭 If you have feedback or items you’d like to include, feel free to reach out.

🤝 If you’d like to become an MCJ community member, apply today.

💡 Have a climate-related event or content topic that you'd like to see in the MCJ newsletter? Email us at content@mcjcollective.com

Another issue I've heard about bioplastics is that there is not enough biogenic carbon on the planet to completely replace the amount of conventional plastic we produce every year. Have you heard anything like this, or is it not of concern to you?