From Lab to Grid: What It Takes to Make Fusion Energy a Reality

by Doug Perkins, Head of Business Development at Pacific Fusion

The story of human civilization is the story of energy. Each leap forward, from wood to coal to oil, has unlocked new levels of prosperity and possibility. Today, we are on the cusp of another inflection point: a world of exponential energy demand, driven by electrification and AI. Meeting that demand with abundant energy will unlock breakthroughs across every sector of society, from medicine to manufacturing to space exploration – so long as that energy is affordable.

Fusion energy, the same process that powers the stars, offers an attractive solution to this problem. It is safe, limitless, and now, within reach. For the first time in history, we have a clear path to harness this stellar power here on Earth — not in 30 years, but within the next decade.

The decisive factors will be time and cost. Fusion will not transform the world until it can deliver power cheaper than fossil fuels and deploy at scale even faster. Building on recent scientific breakthroughs, the primary remaining challenge is engineering systems that can operate reliably, at scale, and at a price point that’s cost competitive.

Dozens of companies are racing to reach that milestone. Every dollar invested, every advance in design and supply chains, and every supportive policy brings us closer to a future where fusion is not just possible, but can also outcompete all other power sources on cost and scale.

Energy’s Holy Grail

The prospect of fusion energy has captivated scientists for more than 100 years, since British astrophysicist Sir Arthur Eddington first hypothesized in the 1920s that stars released energy through the fusion of atoms. Humankind has always looked up to the sun as the source of life and energy. Well, it’s also powered by fusion energy, which works by taking two hydrogen atoms and squeezing them together at high temperature and pressure until they fuse into helium and release energy. It’s a process that, according to Einstein’s famous equation E=mc2, converts a small amount of mass into huge amounts of energy. That energy can be harnessed to generate limitless amounts of emissions-free electricity — provided we can produce it reliably and affordably enough here on earth.

Actually achieving fusion has eluded scientists for decades, largely because recreating the sun’s conditions required levels of heat and pressure that pushed the limits of available technology – until a series of breakthroughs reframed the timeline.

Everything changed in December 2022. After decades of research, a series of scientific breakthroughs charted a real path toward viable fusion energy. First, scientists at the National Ignition Facility at Lawrence Livermore National Lab in California achieved controlled fusion ignition, demonstrating the physical conditions needed for commercial relevance. Around the same time, the Z Machine, 1,000 miles away at Sandia National Labs in New Mexico, showed that a more energy-efficient path to ignition was possible using pulsed electrical current rather than lasers.

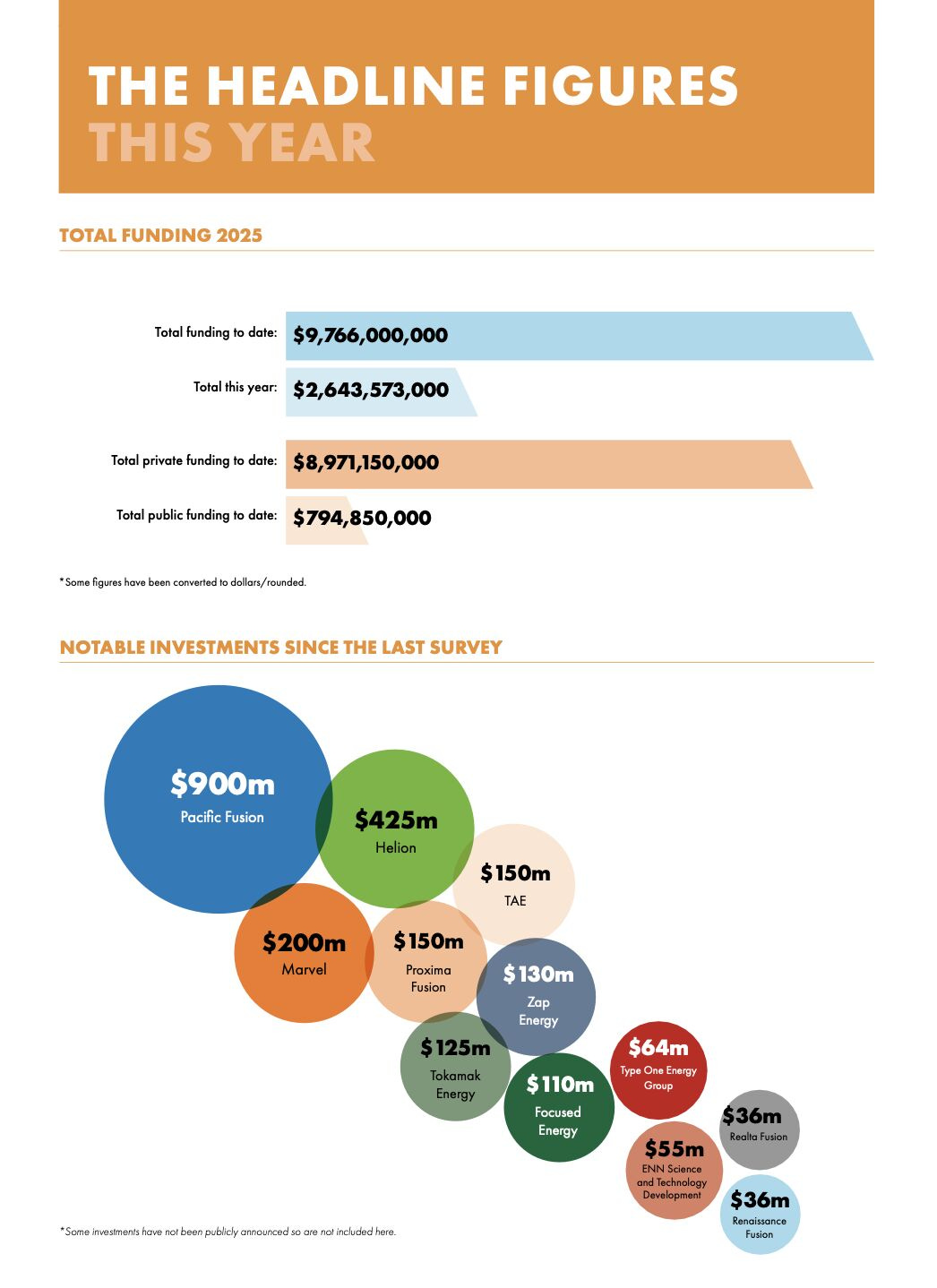

Neither facility was designed to release net energy or generate electricity, but the breakthroughs energized the private sector. There are now 53 companies around the world actively working to commercialize fusion, according to the Fusion Industry Association. They’ve raised a combined more than $10 billion in private capital, with more than 30% of that raised in the past year alone.

Fusion’s appeal is clear. It uses fuel sources abundant enough to last for billions of years. It’s safe and, unlike nuclear fission, it neither “melts down” nor produces high-level radioactive waste. It’s clean, with no greenhouse gas emissions. Critically, the demand for low-cost, carbon-free, on-demand power has never been higher. The explosion of artificial intelligence is one reason why the U.S. is experiencing electricity load growth at levels not seen since the end of World War II.

The industry is now racing toward the next major milestone: net facility gain — that long-sought point at which a fusion system as a whole produces more energy output than is initially stored. This is essential, but it’s still only part of the challenge. Net facility gain will prove that fusion power is possible, but it won’t prove that it’s yet practical at scale. To become a viable source of low-cost, on-demand electricity deployed fast enough to meet soaring global energy demand, fusion must overcome the same kinds of hurdles that automobiles once faced: building infrastructure, reducing costs, and earning public trust. So while what once seemed like science fiction is quickly becoming real, we must also solve several practical challenges, starting with:

#1 Designing for safety, low-cost and repairability

To compete with existing sources of energy, fusion must be able to deliver reliable power for less than $100 per MWh — an approximate threshold for market viability today. That means:

Reducing capital expenditure for deployment. The rise of modular design has transformed replicable construction, significantly cutting build times and construction costs. This philosophy applies to energy-related megaprojects, too, where replicable modularity in design and speed in iteration can play a critical role in project success. Fusion systems should be similarly modular for affordable deployment, with components that can be shipped in containers and assembled quickly.

Reducing maintenance complexity and increasing operational performance. Fusion systems will inevitably suffer from wear and tear: Plasma-facing surfaces must either survive extreme conditions for extended periods of time or be rapidly and cost-effectively replaced. Systems that are designed with this in mind – with standardized, modular parts, or materials that are durable or self-healing – can minimize downtime for both planned and unplanned maintenance.

Ensuring operational safety. The safety of workers, communities and the environment is paramount. Fusion systems are different from traditional nuclear fission reactors in that they do not produce high-level nuclear waste, have no potential for meltdown, and do not use fissile material. However, like any power plant, it is still essential that they be designed and built for safe operations. Affordable and robust shielding around plasma regions, remote operation and monitoring technologies, and comprehensive safety protocols will be essential.

#2 Building systems for resource availability

The generation of fusion power is just the midpoint of a complex chain of supply and delivery. To ultimately deliver electrons to the grid, we’ll need:

A sustainable fusion fuel economy. Fusion fuel commonly consists of two isotopes of hydrogen, the most abundant element in the universe. Deuterium can be easily extracted from water. Tritium, on the other hand, is rare in nature and requires specialized processes to produce sufficient quantities to support the growth of the new fusion energy industry. The degree of tritium handling complexity scales with its volume. As a result, viable systems must (1) minimize how much tritium is required, (2) engineer systems to produce tritium efficiently, and (3) minimize losses via efficient recycling — all while working with governments to secure stable reserves.

Systems made from simple, domestic building blocks. Fusion systems designed with simple, widely available materials, including components sourced from a broad range of domestic suppliers, will more readily ensure a clear path to widespread deployment. The Fusion Industry Association’s 2025 Supply Chain report warns that the availability of parts at scale remains a serious vulnerability. This is particularly true for fusion systems reliant on inherently rare or expensive materials – or supply chains only available overseas. As the semiconductor industry has shown, robust domestic supply chains are essential for affordable deployment and also for energy and national security.

#3 Appropriate regulation

The fastest way to slow fusion deployment is to lump its regulation together with fission.

Fortunately, in 2024, the U.S. passed the bipartisan ADVANCE Act, which formally clarified that fusion should not be regulated like conventional nuclear fission reactors. This created a path forward for fusion energy, and followed years of detailed deliberation by the nation’s nuclear regulator, the U.S. Nuclear Regulatory Commission (NRC). It served as an acknowledgment that fusion’s safety profile is fundamentally different from that of fission’s. Implementing rules anticipated for release by the end of 2027 will provide the needed regulatory momentum for future fusion deployment.

What matters now is implementation, especially at the state and local level, to ensure the timely approval of fusion power plants. By following federal direction, state policymakers can craft a regulatory framework that supports safe deployment with clear but flexible rules, consistent timelines, and efficient processes.

Building for the future

Achieving net facility gain may be the next major breakthrough, but realizing this vision of abundant commercial fusion energy will depend upon solving a series of manufacturing and regulatory challenges.

These hurdles are not new: nearly every major energy source or revolutionary technology has faced a similar landscape. For cars, deployment accelerated once the Ford Model T transformed mass manufacturing with the assembly line, greatly lowering costs and democratizing ownership. While fusion is uniquely situated to address the complex challenges of the coming decades, it too will require favorable conditions to turn scientific progress into scalable power.

That moment is now within reach. The breakthroughs of recent years have de-risked the science; what remains is the race to industrialize the technology. Companies that can deliver reliable, modular systems, build resilient supply chains, and navigate regulation with speed will unlock an energy source with virtually no fuel constraints and a cost curve that only improves with scale. The next frontier is not proving that fusion works, but proving it works cheaper and faster than the alternatives.

🎙️ The Inevitable Podcast

🐺 Colossal Biosciences is rewriting the rulebook on life itself. CEO Ben Lamm shares how his team uses synthetic biology and AI to resurrect extinct species—from dire wolves to future woolly mammoths—and build a venture-scale de-extinction platform. Listen to the episode.

💎 Circularity Fuels is turning waste carbon into high-value products, and starting with lab-grown diamonds. CEO Stephen Beaton shares how this bold beachhead market proves their reactor tech before scaling to sustainable aviation fuel. MCJ is proud to be an investor in Circularity Fuels. Listen to the episode and check out Stephen’s Guide to First-Market Fit for Climate Tech Founders.

🎥 The Lean Back

Electrifying marine vessels with Arc Boat Company.

👩💻 Climate Jobs

Check out the Job Openings space in the MCJ Collective Member Hub or the MCJ Job Board for more.

Training Manager at Aalo Atomics (Idaho Falls, ID)

Validation Engineer at Base Power Company (Austin, TX)

Operations Manager at Charm Industrial (Fort Lupton, CO)

Staff Software Engineer at Crusoe (SF, CA)

Senior Mechanical Engineer at Kodama (Remote)

Senior Accountant at Lightship (Broomfield, CO)

Senior Director, Software Engineering at The Nuclear Company (Seattle, WA)

Head of Product Marketing at Patch (SF, CA)

Head of HR & Recruiting at Runwise (New York, NY)

Director - Utility Business Development at Weave Grid (SF, CA)

Sr. Process Engineer at Windfall Bio (Houston, TX)

MCJ Newsletter is a FREE email curating news, jobs, Inevitable podcast episodes, and other noteworthy happenings in the MCJ Collective member community.

💭 If you have feedback or items you’d like to include, feel free to reach out.

🤝 If you’d like to join the MCJ Collective, apply today.

💡 Have a climate-related event or content topic that you’d like to see in the MCJ newsletter? Email us at content@mcj.vc