Chemical manufacturing is, by its nature, one of the largest industry subsectors of direct carbon emissions. In 2021, primary chemical production was responsible for 925 Mt of CO2. Given the industry runs on fossil fuels, these massive emissions should not come as a surprise. If you look around, we’re surrounded by products made from carbon-intensive chemicals, such as plastics, fertilizers, and cement. Many of these are shipped to the U.S. from China or other parts of Asia where they are produced. Chemical manufacturing typically happens through petrochemistry or fermentation. The former uses toxic feedstock at high temperatures and results in harmful waste. Fermentation also requires high amounts of energy and waste with even lower yields. Regardless, decarbonizing the chemical manufacturing and production process is imperative to a cleaner, more sustainable world.

Solugen offers a solution. The Houston-based company has developed a completely new process for creating 90% of the world’s chemicals by combining the best elements of petrochemical processing with the best aspects of fermentation. Solugen’s molecules are high-performing, cost-competitive, and carbon-negative. The company’s clean process eliminates noxious waste of chemical manufacturing and can be applied across our most needed industries, including food, water, energy, infrastructure, and hygiene.

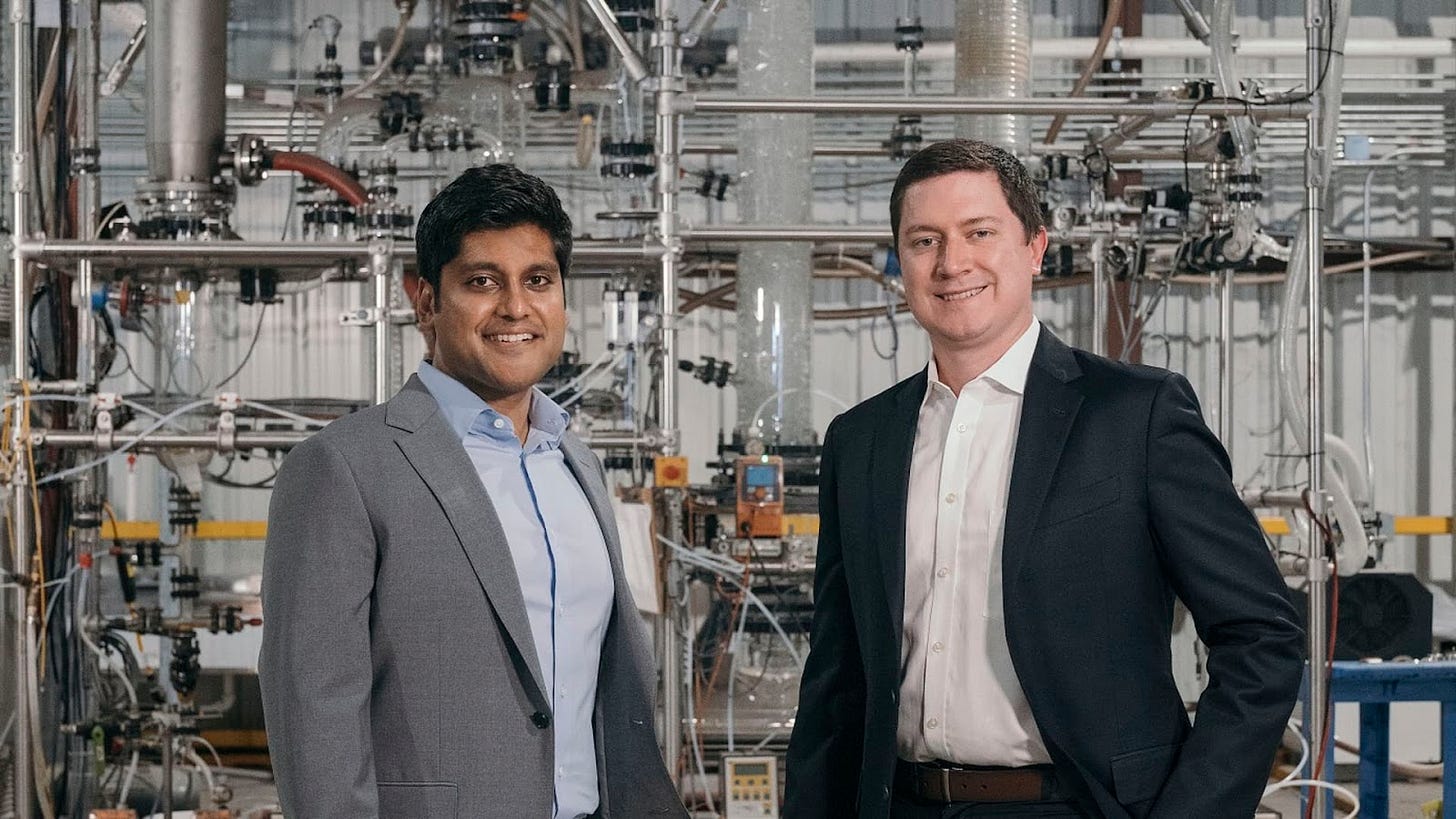

At MCJ Collective, we’ve supported startups tackling the ubiquitous problem of plastics using synthetic biology. As a growing area of research and innovation, we’re delighted to welcome Solugen to our portfolio and back co-founders Gaurab Chakrabarti and Sean Hunt as they bioengineer the future of chemical manufacturing.

What is Solugen?

At the most basic level, Solugen uses renewable resources, like biomass or carbon dioxide, to make many of the chemical materials we interact with daily. They’ve built the first clean molecule factory, the Bioforge in Houston, Texas, that operates without toxins, carcinogens, or emissions. By satisfying four key parameters — biobased feedstocks, high selectivity, high yields, and high throughput — the Bioforge can convert inexpensive feedstock directly into valuable product molecules without generating any waste.

Sugars, water, catalysts, and air make up Solugen’s feedstock. The company’s products run the gamut from water treatment chemicals to making a range of materials, such as polyester, plastics, solvents, detergents, resins, medicines, and antibiotics.

Why Did We Invest?

Compelling Founder-Market Fit

Solugen’s co-founders met while trying to solve similar problems from different angles.

As a physician-scientist, Gaurab Chakrabarti took an oath to first do no harm—and for him, that goes beyond patients or medicine. Serving as the company’s CEO, Gaurab believes in using biology in unconventional ways to solve incredibly complex problems. He studied computational neuroscience as an undergraduate at Brown University and received his MD & Ph.D. in cancer biology and enzymology at the University of Texas. He is an author or co-author of more than 20 peer-reviewed publications and patents and is a Forbes 30 Under 30 in Industry and Manufacturing.

At Solugen’s CTO, Sean Hunt focuses on utilizing novel metal catalysts, scaling up proprietary chemoenzymatic process technologies, and developing the framework for Solugen’s molecule factories: the Bioforge. His engineering endeavors have spanned a wide range of industries and applications, working as a fuel cell engineer for the U.S. Navy, a vaccine and API process engineer for Merck in Singapore, and a Cocoa Puff engineer at General Mills. Sean holds a Ph.D. in chemical engineering from MIT where he studied renewable energy and green chemical manufacturing on metal catalysts as an NSF graduate research fellow. He is a Forbes 30 Under 30 in Industry and Manufacturing and co-author of more than 20 peer-reviewed publications and patents.

Scaling Output and Delivering Impact

Using proprietary engineered enzymes, Solugen scales synthetic biology quickly and efficiently. The company has grown from a small pilot plant in the water sector to a commercial plant and several different industries in just 5 years. Much of this success can be attributed to Solugen’s Bioforge. At a 10,000 ton per year capacity, the Bioforge scales new molecule production 1 million fold in months instead of decades. The company’s solution is already delivering impact across several critical industries from crops to cleaning supplies. For example, Solugen’s micronutrients help improve crop yield and quantity, while their water treatment chemistries treat and preserve water sources. Its biobased detergents and industrial cleaners are safe, sustainable, and effective. And Solugen’s products are also poised to build stronger and longer-lasting materials for building infrastructure, as well as energy solutions to accelerate the clean transition.

Solugen has an ambitious vision, which if successful could radically disrupt the chemicals industry: remove the CO2 equivalent of taking 2M cars off the road; replace 5B bottles worth of non-degradable plastic, and have the capability of making 90% of all chemicals. The company aspires to achieve this vision by 2030, and MCJ is excited to help support its efforts in accomplishing it.

Additional Resources

If you are an accredited investor and want to learn more about being an investor in our fund (to back more great companies like this one!), reach out here, and include your desired quarterly commitment level, accredited investor status, and info on your background and how you could be helpful to the portfolio.