Our Investment in AMP Robotics

Reimagining recycling through AI and robotics

Waste materials, such as aluminum cans, cardboard, and plastics, carry embodied emissions due to the energy and resources involved in their production. Since the 1970s, recycling has been promoted in the U.S. and throughout the developed world as a way to mitigate the pollution and GHG emissions from the use of virgin materials for single-use products. According to The Atlantic, producing aluminum cans from recycled materials is 95% less energy-intensive than manufacturing them from raw materials. Moreover, recycling leads to less waste in landfills, which the EPA says is responsible for 15% of methane emissions in the U.S.

According to The Wall Street Journal, China for decades has been the primary destination for the world’s refuse, importing 45% of global plastic waste since 1992. As China’s burgeoning economy drove demand for raw materials, a robust market for recyclable commodities emerged. However, by 2017 China found itself inundated by the world’s garbage — much of it contaminated with non-recyclable material — and abruptly reversed its stance on importing recyclables through “Operation National Sword.” With that decree by China, the waste commodities market was turned on its head, and the recycling industry found itself with a mound of recyclables and a significantly curtailed market in which to sell it. This sent municipalities in the U.S. scrambling to deal with a pile-up of recyclable waste, leading some communities to shut down their recycling centers or resort to disposal through incineration or landfill.

Much of the challenge the recycling industry faces today relates to its ability to produce commodities that are of high value, as defined by how well they’re separated from non-recyclable waste. Addressing this problem and its underlying costs, AMP Robotics has developed technology that can presently automate up to 75% of a recycling facility's manual sorting operations. We feel fortunate to back CEO & Founder Matanya Horowitz and his team, as they deploy an array of advanced technologies to make recycling more efficient, economically viable, and scalable.

What is AMP Robotics?

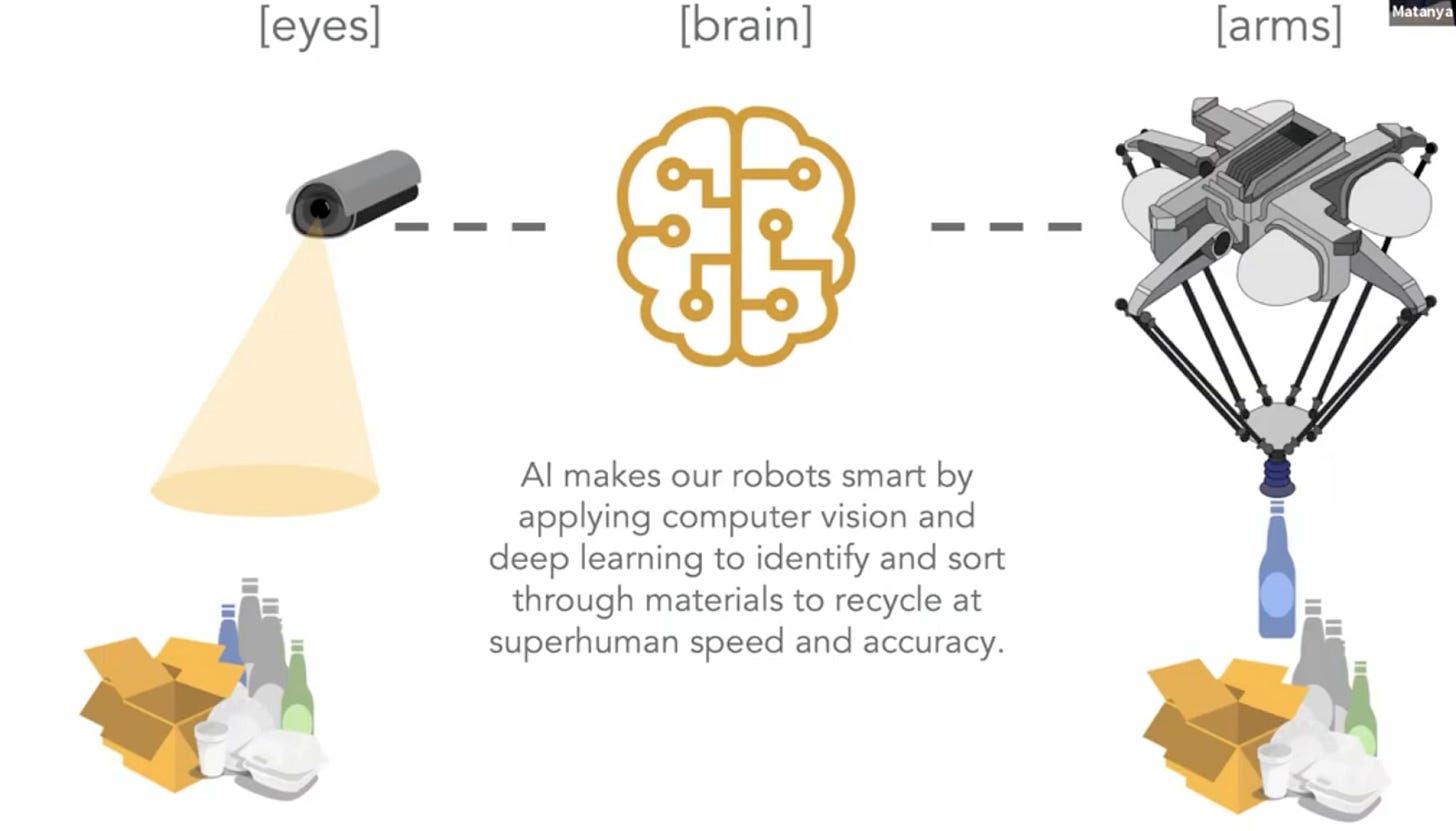

Based in Louisville, Colorado, AMP Robotics develops and deploys AI and robotics technology that enables a recycling facility to drive efficiencies across its sorting process, lower the cost of its operations, and produce higher-value commodities. It does this by integrating off-the-shelf robotic hardware with its proprietary AI and machine vision software.

The company’s flagship product, AMP Cortex™, is a sorting robot that can identify and pull out cartons, aluminum cans, cardboard boxes, and plastics from a fast-moving conveyor belt. It speeds up the sorting process while ensuring recyclables and non-recyclables are accurately separated. To date, AMP has deployed more than 125 robots to recycling facilities throughout North AmericaJapan, and Europe. Able to perform 80 to 120 “picks” per minute (cf. 40 picks per minute by a human sorter), AMP Cortex is able to recover 90% of valuable commodities from a typical sort line and ensure up to 99% purity. The robot can offset the work of two manual operators and can be installed with little to no retrofit as the robot bolts onto the existing conveyor belt. At its core is a vision system that is very effective at sorting through heterogeneous material. For recycling facilities that need to measure the purity of the material produced, the company offers AMP Clarity™, a web-based platform for real-time material characterization.

AMP CEO & Founder, Matanya Horowitz, spoke to Jason in 2020 on the MCJ podcast.

Why Did We Invest?

Strong Founder-Market Fit

We can’t imagine a better-suited founder than Matanya Horowitz at the helm of a robotics recycling company. A self-described lifelong fan of robotics and science fiction, Matanya completed his PhD at CalTech, where he studied control theory, performed research on robotic grasping, and did work commissioned by DARPA. In 2012, he was exposed to “deep learning,” which allows robotic systems to see the world. While he knew very little about recycling at first, he saw the potential applications for this technology and visited recycling centers to learn about the intricacies of the business. His early work eventually led him and his team to developing proprietary neural networks and AI infrastructure.

Addresses The Acute Pain Felt By The Recycling Industry

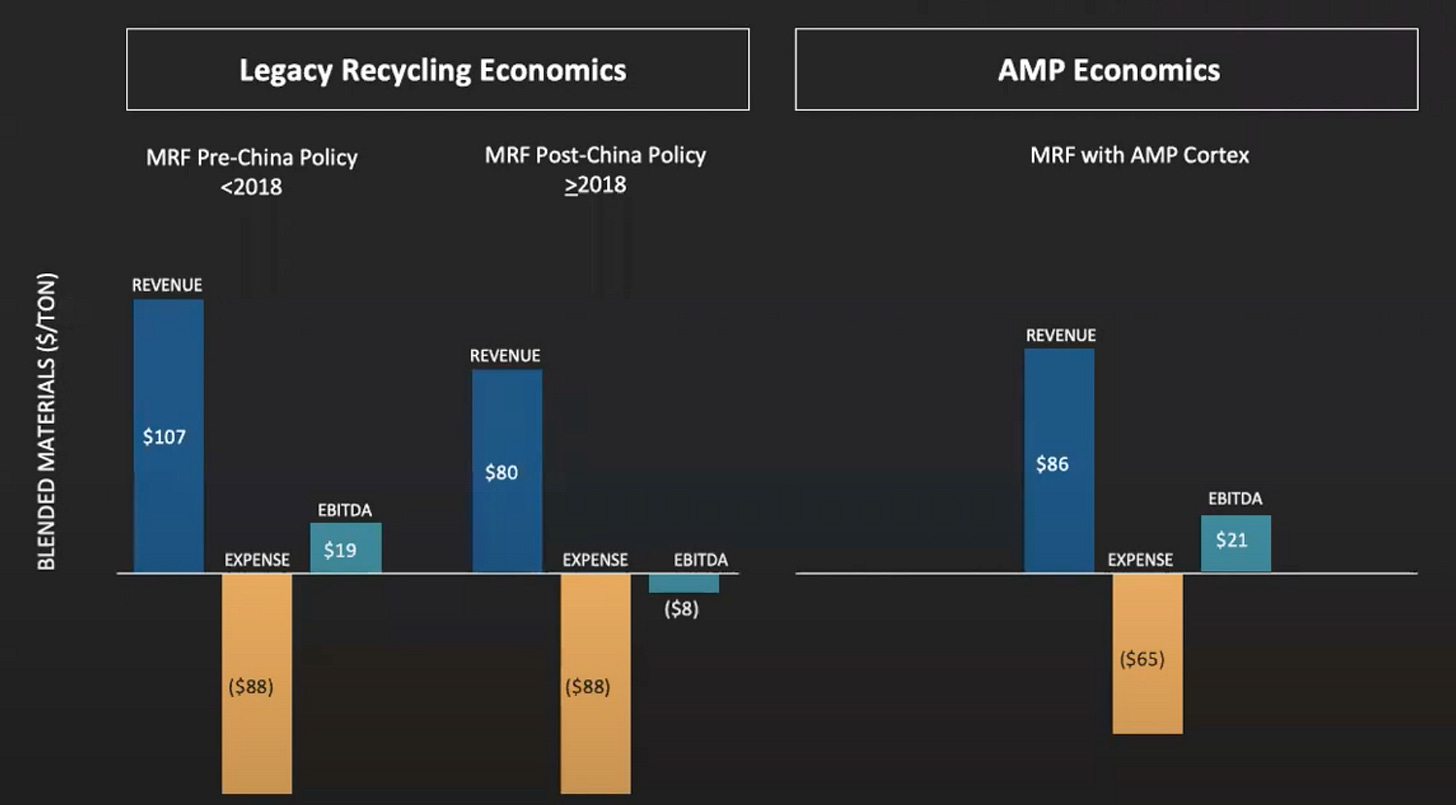

Today, recycling facilities rely on manual labor to pick and sort waste. The work is tedious and, due to the occasional presence of dangerous items (e.g. syringes), is not without risk to human workers. As a result, the labor force experiences high turnover, which COVID-19 has exacerbated. In addition, due to China’s policy reversal, the unit economics of recyclable materials no longer work. While the cost of processing and sorting remains the same (~$90 per ton), revenue has declined markedly by 25%. Because recycling’s economic viability is under threat, landfills are positioned as a cheaper, albeit environmentally harmful, alternative to dispose of recoverable waste.

As a result of China’s “Operation National Sword” policy in 2017, materials recovery facilities (MRFs) have seen negative unit economics as a result of decreased revenue and processing costs that remain high.

Through automation, AMP Robotics is able to reduce the processing cost of the entire recycling facility by nearly 30%, allowing recycling companies to better manage lower revenues; moreover, it can produce recyclables that are of superior quality because they are better sorted.

A Clear Climate Impact

As mentioned earlier, ineffective waste sorting leads to biodegradable material decomposing in landfills and a substantial amount of GHG emissions, in addition to the emissions footprint associated with using virgin materials to produce single-use products. Fundamentally, by enabling the recycling industry to become more efficient and economically viable, AMP Robotics’ technology is diverting waste from landfills and driving greater re-use of recyclable materials.

Beyond MRFs, AMP Robotics’ solution has applications in other industries, such as construction and demolition materials, electronic and organic waste, and automotive shred. We strongly believe the company is well positioned to be the leader in automated waste management, and to revolutionize how humanity recycles.

Additional Reading

If you are an accredited investor and want to learn more about being an investor in our fund (to back more great companies like this one!), reach out here.